In the neural network of industrial automation, smart manufacturing, and IoT systems, industrial switches play a pivotal role as data hubs, responsible for the real-time and reliable transmission of massive control commands and production data. However, typical industrial environments—such as factory floors, power facilities, or rail transit systems—are saturated with complex electromagnetic noise generated by variable frequency drives, high-power motors, relay contacts, and wireless communication devices. This interference, characterized by its wide spectrum and high intensity, easily couples into the switch’s internals via power and signal lines. In mild cases, it can cause data packet errors and increased network latency; in severe cases, it can lead to port failures or system crashes, directly threatening the continuity and security of production lines. Faced with this formidable challenge, feedthrough capacitors have emerged as core components for enhancing the electromagnetic immunity of industrial switches and ensuring the unimpeded flow of data, thanks to their exceptional high-frequency characteristics and structural reliability.

The efficacy of feedthrough capacitors is rooted in their innovative “through-type” architecture. Unlike ordinary multilayer ceramic or electrolytic capacitors, they eliminate the parasitic inductance introduced by traditional leads or pads, enabling high-frequency currents to follow the shortest path through the dielectric directly to ground. This design allows their equivalent series inductance (ESL) to be as low as below 1nH, while extending their self-resonant frequency (SRF) into the GHz range. Consequently, when dealing with high-frequency interference commonly found in industrial environments—ranging from tens of MHz to hundreds of MHz—feedthrough capacitors can still exhibit extremely low impedance. This provides an efficient and direct discharge channel for noise, preventing it from reflecting, coupling, or radiating within the circuit.

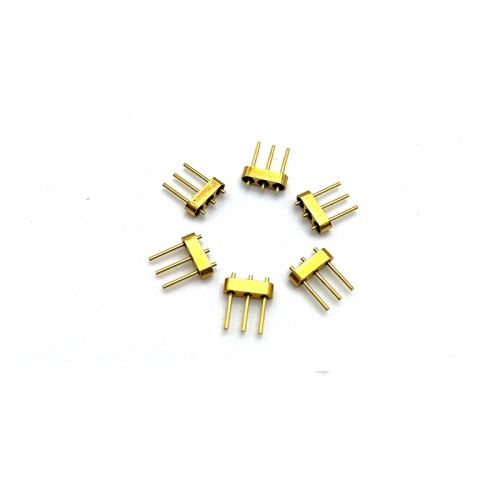

It is worth noting that to meet the extreme reliability requirements of industrial scenarios, industrial-grade feedthrough capacitors often resin sealing or glass sintering processes. They are designed to operate within industrial temperature ranges of -40°C to +85°C or even wider, and can withstand high humidity, vibration, and shock. Their metal housings are typically designed for bolt mounting or soldering, ensuring a large-area, low-impedance (<10mΩ) connection with the switch’s metal chassis or grounding busbar. This establishes a comprehensive high-frequency noise defense system, spanning from the chip level to the system level and covering both power and signal paths.

As the Industrial Internet evolves toward higher speeds, lower latency, and greater reliability, the data-bearing pressure on industrial switches continues to grow. Feedthrough capacitors, serving as “purifiers” and “stabilizers” of their internal electromagnetic environment, are also advancing toward lower ESL, higher SRF, smaller form factors, and integrated filtering and protection functionalities. They stand as an invisible cornerstone, ensuring the resilience of modern industrial networks amidst electromagnetic storms.