As a manufacturer with over 20 years of experience in capacitors and EMI/RFI filters, LCA possesses complete in-house capabilities from material selection to final inspection.

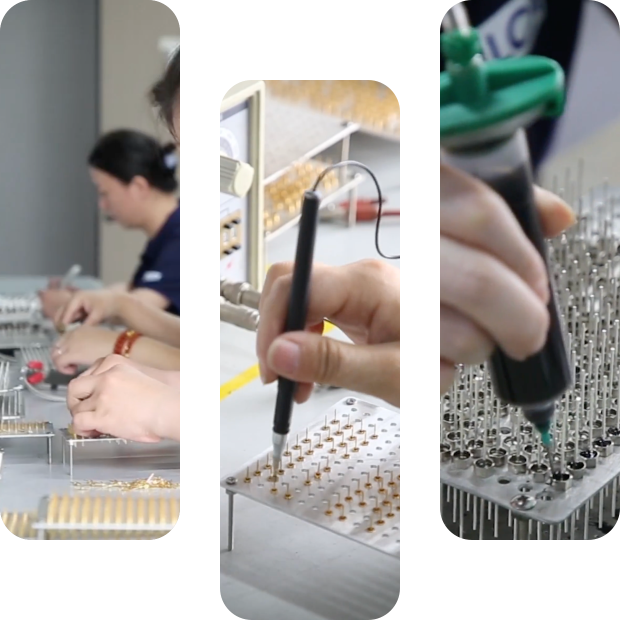

Our production system integrates automation, precision testing, and professional engineering expertise, enabling both high-volume standard production and customized component development.

The company owns a self-owned factory with an area of 2,000 square meters, which provides a solid production space foundation and can offer sufficient site support for production activities.

Our advanced production lines cover the full process. Our company has continuously introduced advanced equipment, such as automatic dispensing machines and CNC engraving machines, enabling automated product packaging and independent processing of tooling parts. After introducing new equipment in 2019, it has been able to independently develop and produce ultra-high voltage capacitors.

All equipment undergoes regular calibration and maintenance to guarantee product consistency and long-term reliability.

The introduction and use of these equipment have improved the degree of production automation and production efficiency, and helped ensure the stability and consistency of product quality.

With modular and flexible manufacturing systems, we can efficiently respond to any production volume—from small pilot runs to high-volume mass production.

Quality defines LCA’s competitive edge. We maintain a strict quality control system that includes:

All procedures are carried out under ISO 9001:2015 and IATF 16949 standards, with continuous oversight and optimization by our engineering team.

We understand that every application has unique technical requirements.

LCA offers comprehensive customization services, including:

From commercial electronics to defense, aerospace, and medical systems, we deliver solutions that meet the most demanding reliability standards.

LCA maintains a robust global supply chain network to ensure:

Standard stock products are typically shipped within 3–7 working days, while customized solutions are scheduled according to project complexity.

Capacity means nothing without consistency.

Every process at LCA reflects craftsmanship and technical expertise, driven by the belief that

LCA is customer demand-centric. With professional technical capabilities, rigorous implementation processes, and considerate full-cycle services, it creates exclusive solutions for customers with diverse needs!