In the vast landscape of electronic components, the feedthrough capacitor is quietly radiating its unique brilliance. As a specially constructed three-terminal capacitor, its hollow-core structure demonstrates irreplaceable value across numerous applications.

A visit to the feedthrough capacitor production line of LCA Electronics Technology Co., Ltd. (hereinafter referred to as LCA) reveals rows of modern machinery steadily producing various models of feedthrough capacitors. From initial production to final market release, each capacitor undergoes multiple layers of rigorous inspection.

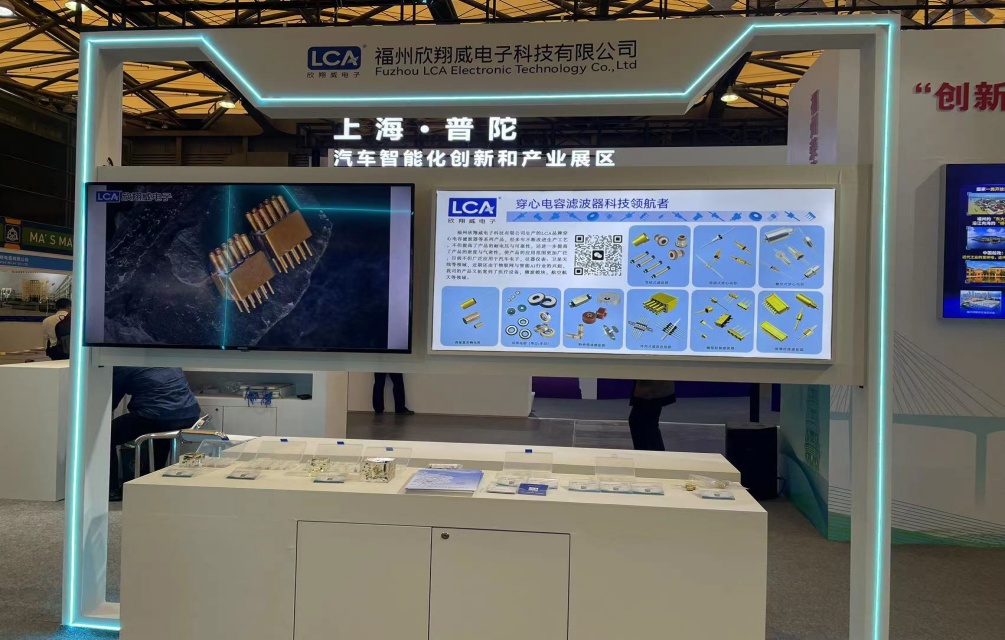

LCA is a high-tech enterprise specializing in the R&D and production of EMI feedthrough capacitor filters, micro RF filters, insulating terminals, and other filter series. The company owns a factory area exceeding 2,000 square meters and boasts a strong R&D team dedicated to new EMI/EMC filter products, developing over 60 new product projects for customers annually. Core technologies have obtained multiple state-recognized intellectual property rights, demonstrating industry-leading manufacturing capabilities, with all raw materials now localized.

“The core manufacturing technology behind our feedthrough capacitors is the ‘Dry-Pressing Process.’ This powder compaction molding technique not only ensures high density, precision, stability, and voltage resistance but also enables a more compact product size,” explained a technical specialist from LCA.

Through years of R&D and process refinement, LCA has further enhanced product density and hermeticity, improving voltage resistance and reliability. The company has successfully developed hundreds of feedthrough capacitor models. Deep expertise in ceramic material technology, combined with EMI filter specialization, enables LCA to offer an unparalleled series of EMI filter products.

From the challenging early stages of R&D and small-batch production to large-scale sales and expansion into international markets, LCA has dedicated tremendous effort. By providing reliable quality, excellent service, and competitive pricing, the company has earned a stellar reputation among its customers. It not only meets domestic market demand for feedthrough capacitors but has also attracted numerous international clients seeking collaboration.

Today, LCA possesses not only advanced capacitor production lines and sophisticated testing equipment but also substantial technical expertise. Adhering strictly to the “ISO 9001” Quality Management System, LCA is committed to delivering world-class feedthrough filters.